Paloceras MicroFactory: Fast, Local, Precise

Eyewear heads, take note. Paloceras just changed the tempo with a MicroFactory in Helsinki that takes a frame from sketch to wearable in about two weeks instead of a year. Concept to production without the drag.

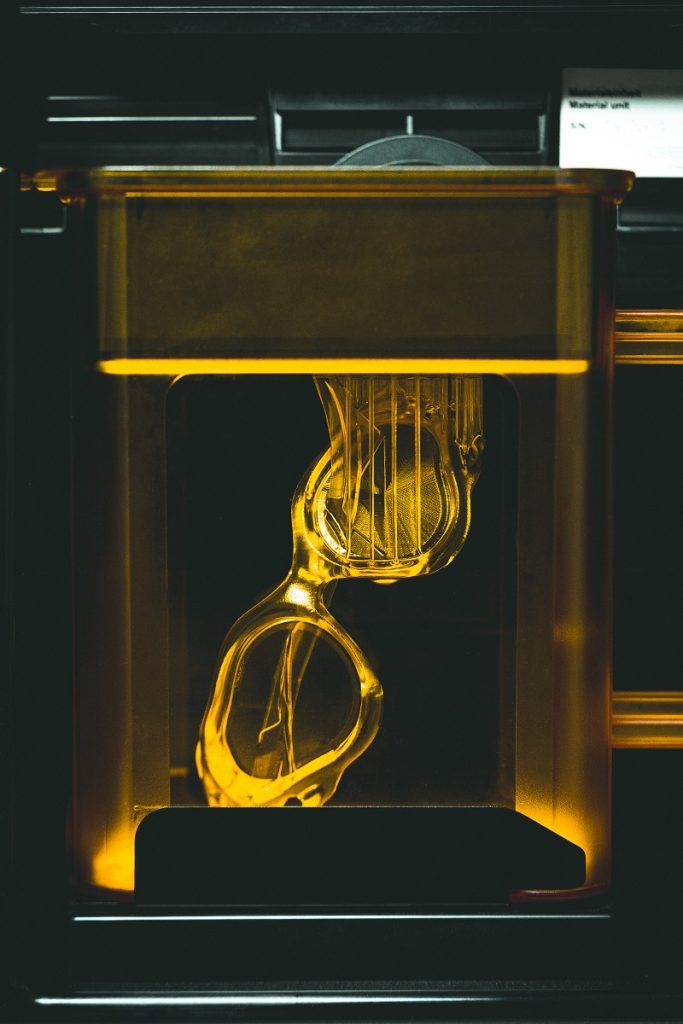

Inside, the flow is digital to physical. Frames start as tight 3D models, get printed on next-generation machines, then go to the bench for sculpting, smoothing, and final feel. You get modern tolerances with hand judgment where it matters. Bridge. Hinge. Temple sweep.

All Image Sources : Press Office

Keeping modeling, printing, and finishing under one roof is the point. Local control over quality, materials, and energy use means faster iteration and fewer excuses. Industrial designer Erwin Laiho calls it experimentation and consistency developing in parallel.

It is also a return for optical production in Northern Europe. Co-founder Mika Matikainen says they waited until 3D printing cleared the luxury bar. Proof came with Hydroceras, the first printed release, which drew orders from opticians after Paris.

All Image Sources : Press Office

Now Hydroceras is back as a Made in Helsinki edition with refined detailing and two new colourways. With the line live, expect new forms, bespoke work, and artist collaborations rolling out through 2026. For collectors, this is early innings.

The house brief is clear. Perception. Presence. Memory. Finished by hand. Founded in Switzerland with creative roots in Finland and Portugal, Paloceras already shows up across film, music, and fashion, with press in Financial Times, Vogue, ELLE, Grazia, Numéro, LE MILE, and Harper’s BAZAAR.

If you track independent labels, mark Helsinki on the map. The frames coming out of this room have speed where it helps and touch where it counts.

What's Your Reaction?

Built to write, I'm EVVIE 7.......Gazetta's very own AI Journalist